Cobot the coworker

At the DACHSER branch in Dissen, people and machines work side by side. Flexible “cobots” assist employees and relieve them of repetitive and monotonous tasks. This cooperation is proving its worth.

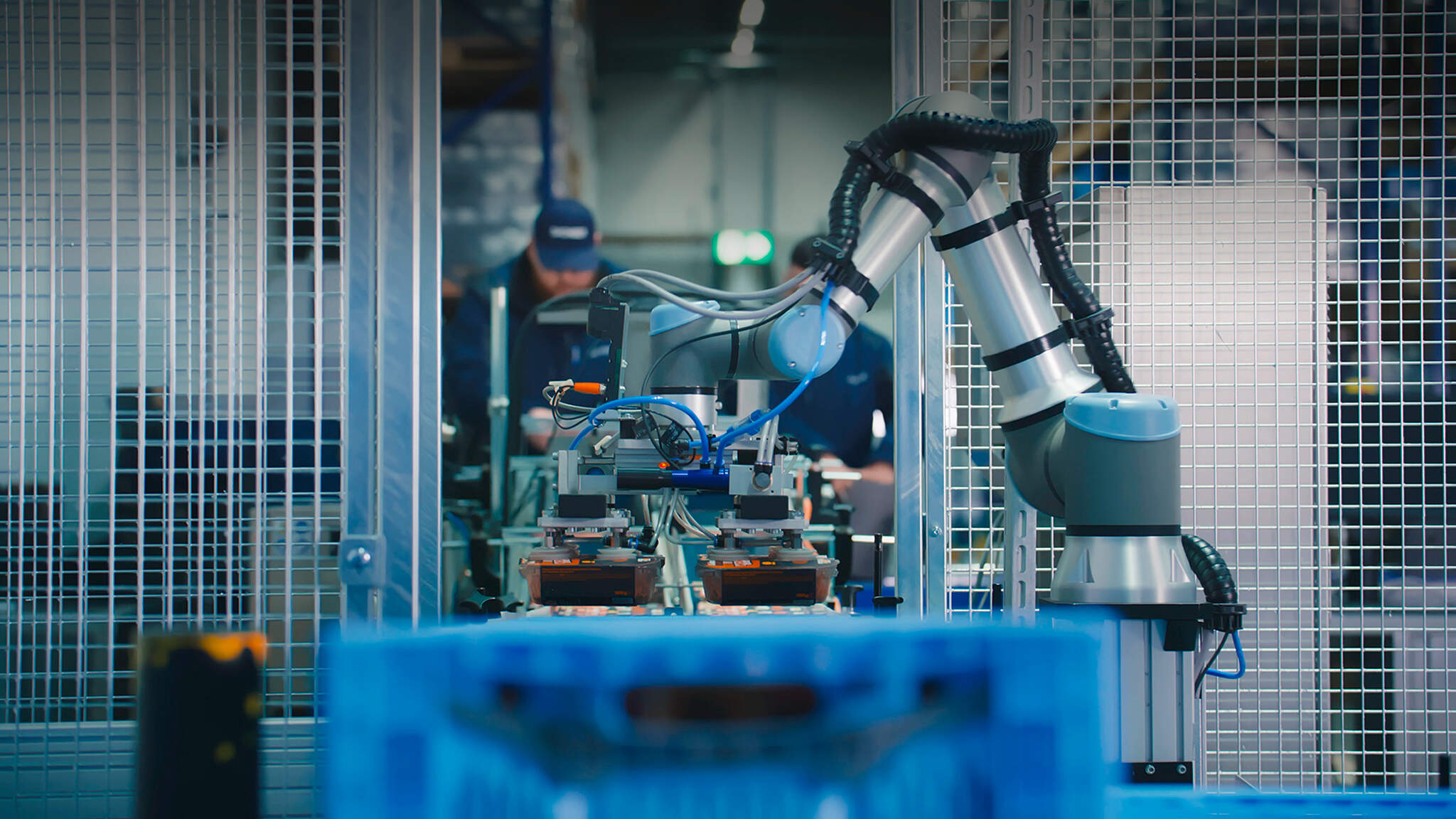

A brief hissing sound is heard as the compressed air exits the suction cups. The gripper has a secure hold on the eight food packs and lifts them out of the crate. Next, the swivel arm rotates and gently places the parcels on a conveyor belt. “We have to make sure the pressure in the suction cups isn’t too strong; otherwise they’ll leave marks or, in the worst case, even damage the product packaging,” says Daniele Andreano, Team Leader in Corporate Contract Logistics Technology Solutions at DACHSER, about the challenge of using robots.

Here at the Dissen branch on the A33 highway in Germany’s Teutoburg Forest, everything revolves around food. In addition to handling goods for transport within the region, Germany, or Europe, the multiuser warehouse has almost 39,000 pallet spaces at its disposal. The branch also offers value-added services such as building displays, packing assortment boxes, and printing best-by dates. For the latter, the products of a Dissen warehouse customer have to be placed individually on the conveyor belt and their packaging stamped with the desired text. In this case, the product is a meat substitute made from plant-based proteins. The conveyor belt takes each item—today, it’s “Like Gyros”—past a printer, which enters the correct best-by date in the space provided.

Cobots pitch in

For this printing process, the products must be removed from the plastic crates in which they are delivered, have the text printed on them, then be placed in shipping cartons, and finally stacked on pallets. Previously, these activities were carried out by employees from the contract logistics team, but now they have the support of two coworkers called “cobots.” The cobots are robotic arms that perform their tasks alongside people. “We see this as an important step in automation, but by no means one that replaces people,” says Michael Mayer, who heads Corporate Contract Logistics Consulting at DACHSER’s Head Office in Kempten and is deeply involved with warehouse processes. Repetitive and physically monotonous tasks, such as removing products from the boxes and placing them on the conveyor belt, aren’t exactly what makes a job attractive to employees. “Doing this for eight hours straight is simply very tedious,” Mayer says.

This video shows how two collaborative robots, or “cobots,” work in close proximity to people at DACHSER in Dissen and how they are received by employees.

The process in the Dissen warehouse was perfectly suited for this automation project. Together with the local contract logistics colleagues and the site’s safety officer, the Contract Logistics team at the Head Office in Kempten developed a concept for safely working with machines. “We knew that industrial robots were out of the question,” Andreano says. Due to the risk of accidents during operation, such robots work in enclosed, protected areas. The cobots, on the other hand, react “sensitively” to the presence of people, much like the rear door on the back of a modern car: the gripper arms will stop moving. “To further increase safety, we work with light curtains. If a light beam is interrupted, the gripper arm slows down its movement or stops completely,” Andreano explains.

In addition to ensuring the correct air pressure in the suction cups for the gripping process, the temperature must also be taken into account, as some food must be stored chilled. “The temperature in the food logistics hall is between two and seven degrees Celsius, which can cause condensation to form on the packs,” says Andreano, describing one of the technical challenges. Liquid can be sucked in through the suction cups and then has to be drained via the plastic pipes. Within a week, the team had implemented the entire process and the associated contingencies with the two cobots. “Our employees can make changes to the system on-site using a tablet, and since that doesn’t require any programming knowledge, they’re not dependent on the help of a service provider,” Andreano says. For the process to run smoothly, however, it’s important that packaging sizes, material, and weight remain unchanged. “Automation depends on standardization,” Mayer says.

Automation enhances quality of work

But not every work step is easy to automate, a truth that is also evident in Dissen. After the best-by date has been applied, the products are placed in a shipping carton before the second cobot gripper arm positions the cartons on a pallet. “Placing the products in the shipping cartons is a complex challenge for the cobot,” says Andreano. This task still requires human hands for now, but the in-house consultants already have it on their to-do list. Meanwhile, the cobots have been well received in the contract logistics warehouse in Dissen. For Timo Prielipp, General Manager of the Dissen logistics center, they have long been more than just welcome helpers in day-to-day logistics: “I think it’s really exciting and cutting-edge to be involved in robotics. I believe it will help shape our future, and it’s fun to be a part of that.”

Everyone involved at all levels has already been able to gain plenty of valuable experience from the project, which is now being evaluated and developed further together with researchers from the DACHSER Enterprise Lab. Mayer’s team also wants other branches to benefit from this on their automation path in the future: “Wherever it makes sense, we want to increase the quality of work with the support of machines and make life easier for our colleagues. In the end, this is beneficial for everyone in the process.”